AOP (All-Over Print) and DTG (Direct-to-Garment) are two leading textile printing techniques, each with unique strengths. As demand for personalized items like custom tote bags, custom shirts, and custom body pillows grows, understanding their differences helps in choosing the right method. From printing processes to design capabilities, each approach offers distinct advantages depending on the intended use.

AOP (All-Over Print)

Process

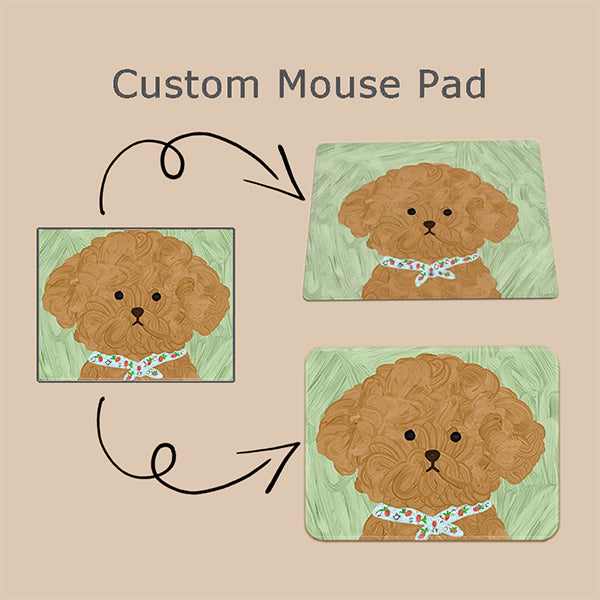

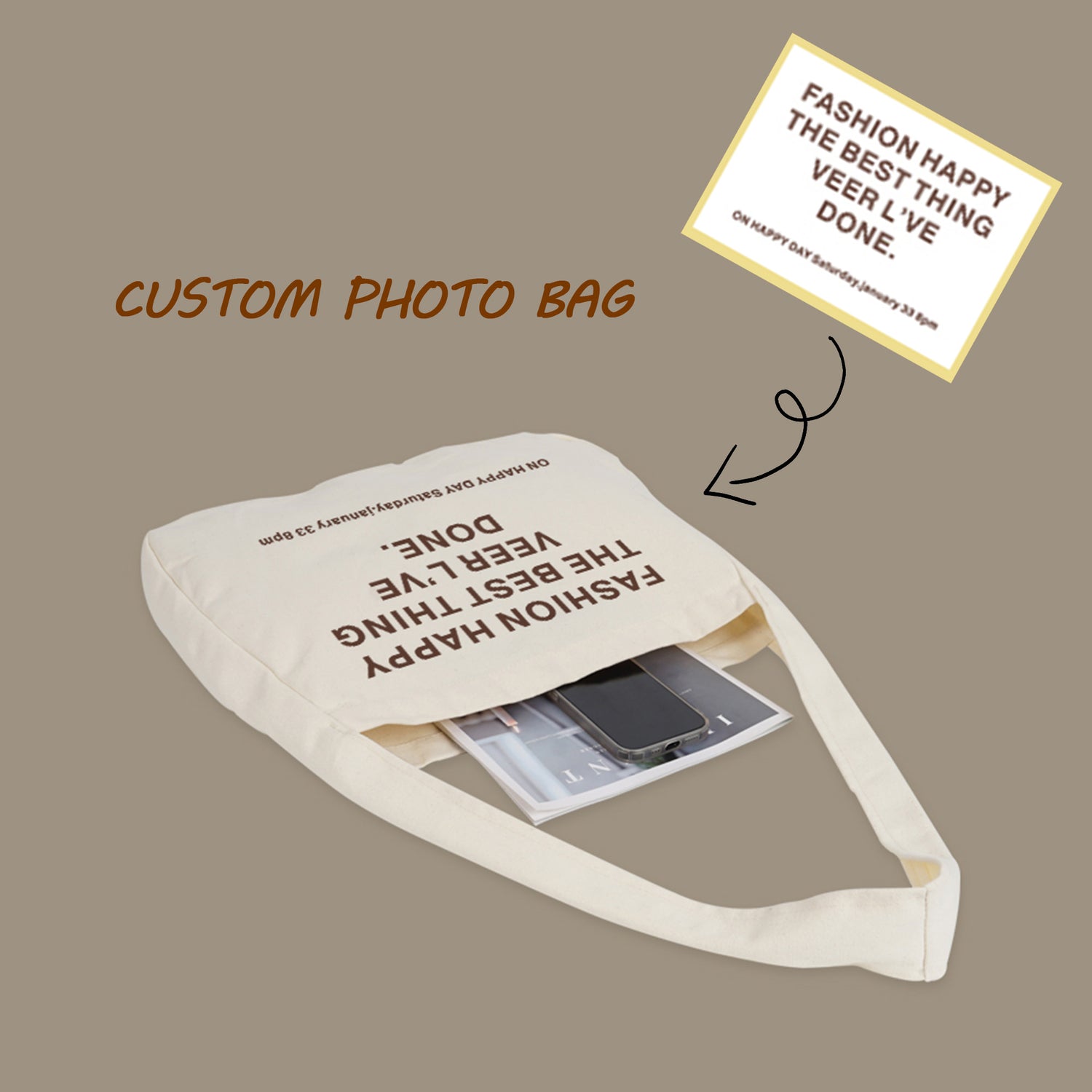

AOP begins with creating a digital design that is printed onto a large sheet of transfer paper. Once the design is ready, this paper is heat-pressed onto the fabric, ensuring the design covers the entire surface. This method allows for vivid and dynamic prints that can wrap around seams and edges, making it particularly suitable for items like custom crossbody bag and fashion apparel.

Capabilities

One of the standout features of AOP is its ability to handle intricate, large-scale designs. Whether you're looking to create a vibrant, all-encompassing graphic for a custom shirt or a striking pattern for home décor items like curtains and bedding, AOP can deliver. The technology is tailored for designs that require full coverage and can yield eye-catching results.

Ideal Applications

AOP is particularly popular in various sectors, including:

- Sportswear:Bright, bold patterns are often seen in athletic gear.

- Fashion Apparel:Unique, all-over designs are a trend in the fashion industry.

- Home Decor Items:From curtains to bed linens, AOP brings designs to life.

- Accessories:Bags, phone cases, and other items benefit from the versatility of AOP.

With the potential to create stunning visuals, AOP opens up a world of creative possibilities.

DTG (Direct-to-Garment)

Process

DTG printing utilizes specialized inkjet printers that apply the design directly onto the fabric. This process involves spraying ink pixel by pixel, which allows for intricate and detailed imagery. Unlike AOP, DTG is more suited for designs that don’t require full coverage, making it an ideal choice for custom shirts and hoodies.

Capabilities

DTG is known for its ability to produce detailed, photographic-quality images. This technique can print on a variety of fabrics, including cotton, polyester, and blends. The flexibility in fabric choice makes DTG an attractive option for businesses looking to offer personalized items, particularly for small-batch production and unique designs.

Ideal Applications

DTG printing shines in the following areas:

- T-shirts:Perfect for custom shirts featuring unique graphics or text.

- Hoodies:Ideal for detailed designs on sweatshirts and outerwear.

- Hats:Great for limited print areas that need high-quality results.

- Other Garments:Useful for clothing items with specific design requirements.

DTG is particularly advantageous for brands that prioritize detailed artwork and a diverse range of fabric options.

Key Differences

Understanding the distinctions between AOP and DTG is essential for anyone looking to enter the custom printing market. Below is a comparison of the two techniques:

|

Feature |

AOP |

DTG |

|

Printing Process |

Heat transfer |

Inkjet printing |

|

Design Complexity |

Intricate, repetitive |

Detailed, photographic |

|

Fabric Coverage |

Full surface |

Limited areas |

|

Production Scale |

Large-scale |

Small-batch, custom |

|

Ideal Fabrics |

Synthetic (e.g., polyester) |

Natural (e.g., cotton) |

Choosing the Right Technique

When deciding between AOP and DTG, several factors should be considered:

Design

If your design is intricate, repetitive, and covers the entire garment, AOP is the preferred choice. For detailed, photographic images, particularly those meant for limited areas, DTG will yield better results.

Fabric

AOP is optimal for synthetic fabrics, which work well with heat transfer methods. Conversely, DTG accommodates a wider range of materials, including natural fibers, making it versatile for various products.

Production Volume

AOP is more efficient for large-scale production runs, enabling cost-effective printing of numerous items. If you're looking to produce custom items in smaller quantities, DTG provides a more tailored approach.

Budget

Considering your budget is essential. AOP may be more economical for larger orders, while DTG tends to be pricier for small-batch production. Evaluating your needs against these cost factors will help in making a sound decision.

Both AOP and DTG offer unique advantages, and by understanding their strengths, you can align your project requirements with the appropriate printing method.

Choosing the Right Printing Technique for Your Design

To conclude, AOP and DTG are powerful tools in the textile printing industry, each serving specific needs depending on design complexity, fabric choice, production volume, and budget. AOP is ideal for vibrant, all-over designs on synthetic fabrics, while DTG excels at creating detailed images on a variety of materials, perfect for custom shirts and other garments.

Whether you're creating custom tote bags for a promotional event, designing a custom body pillow for a unique gift, or offering fashion-forward custom crossbody bags, the choice between AOP and DTG will significantly influence the final product's quality and appeal.

For those looking to explore both options, Mydesigndream stands out as a provider that offers comprehensive AOP and DTG services. Their expertise ensures you can find the perfect solution for your custom printing needs, helping to bring your creative visions to life with the right printing technique.